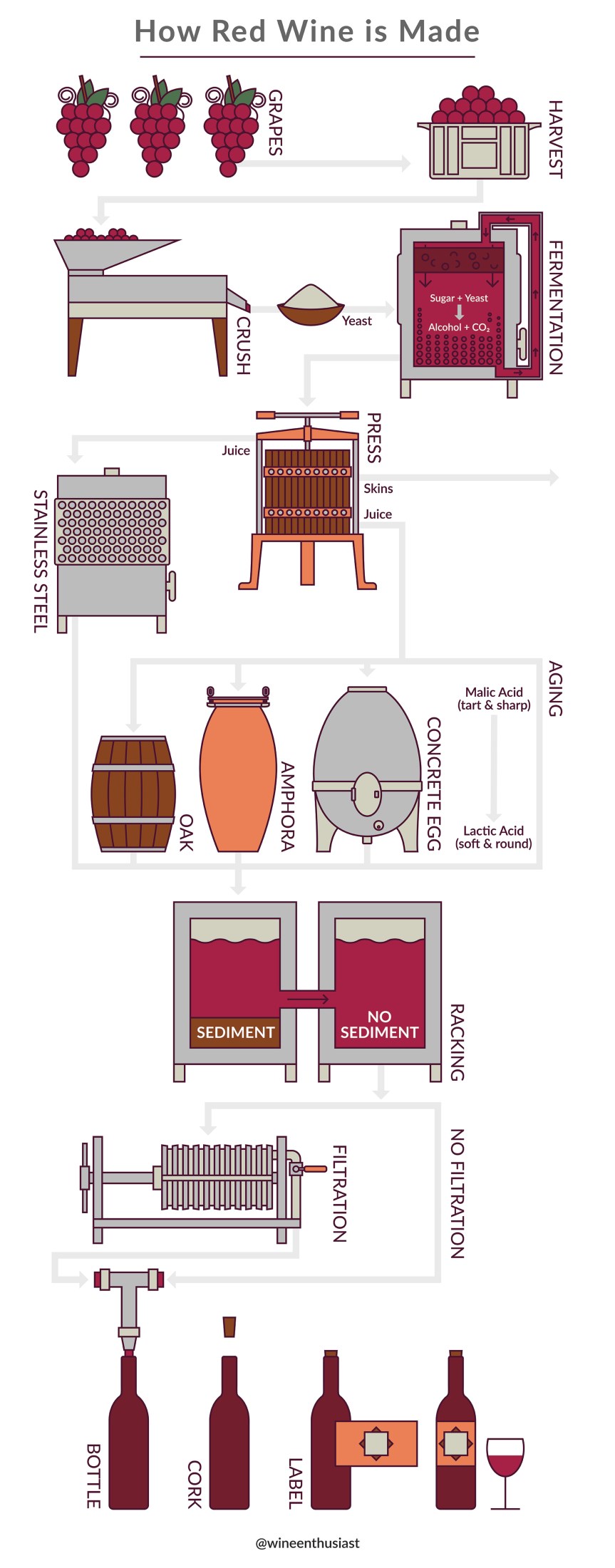

Wineries make red wine today much the same way they did 6,000 years ago in Greece and Persia. Dark-colored grapes are harvested, crushed, fermented, stirred and separated from the skins by a press. Voila! Red wine.

Better containers, presses and cellars have increased quality and efficiency of red wine production many times over, but it’s still essentially a simple process. Red wine production requires no cooking or ingredients besides grapes, yeast and, usually, sulfur dioxide as a preservative.

Red wine is made on the skins

Red wine is made like white wine, but with one major difference. Generally, it ferments with the grape skins and juice combined in a tank or vat. White wines are pressed before fermentation, separating the juice from the skins.

The skin contact in red wine production allows color, flavor and textural compounds to be integrated into the juice, while the yeast converts sugar to alcohol. The skins contain most of the good stuff that gives red wine its color, while the pulp mostly provides the juice.

Harvesting red-wine grapes and the crush

Red wine grapes are ready to harvest in late summer to early fall, several weeks after the initial green color of the grapes has turned to dark red or blue-black, a period called veraison.

Vineyard crews cut the grape bunches or clusters from the vines. That’s either done by hand or a self-propelled machine that shakes or slaps the grapes off their stems and collects the individual berries and juice.

Delivered to the winery, winemakers can also sort out mildewed grapes, unwanted raisins, leaves and debris. Clusters then go through a destemmer/crusher that removes the whole grape berries from the stems and may squeeze them slightly to get the juice flowing. Any juice created at these stages prior to pressing is known as free run. Machine-harvested grapes are already ready to ferment. Continue reading “How Red Wine is Made “